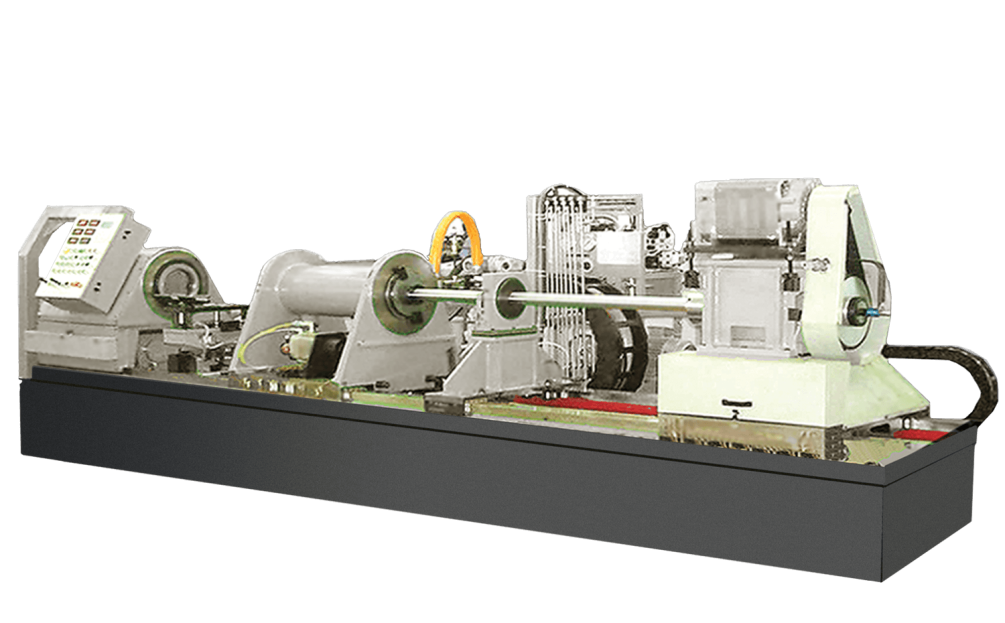

DEEP HOLE DRILLING MACHINES

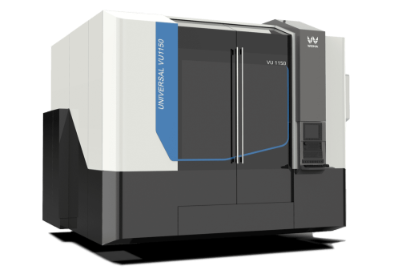

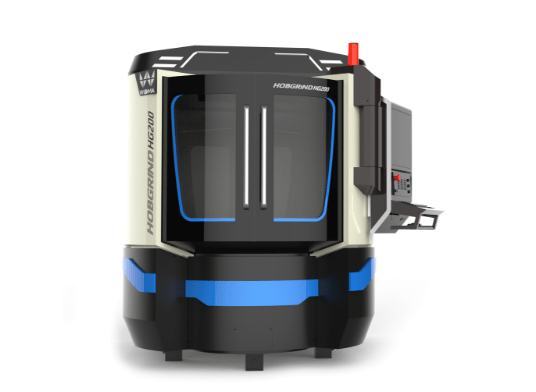

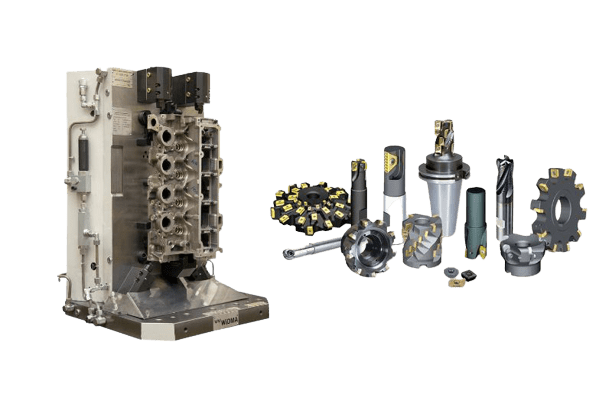

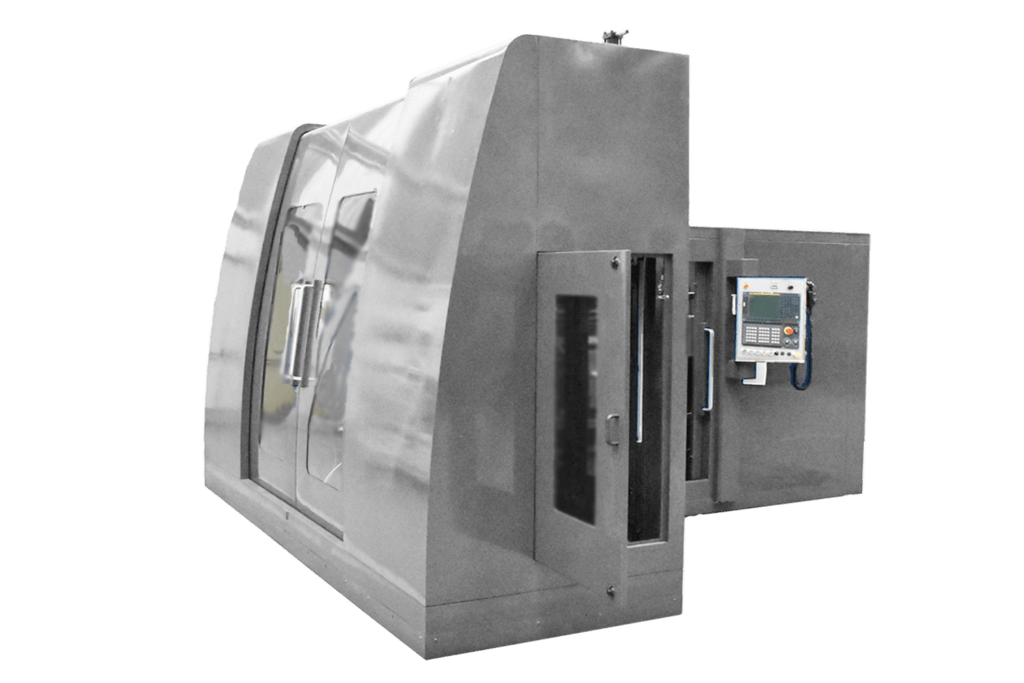

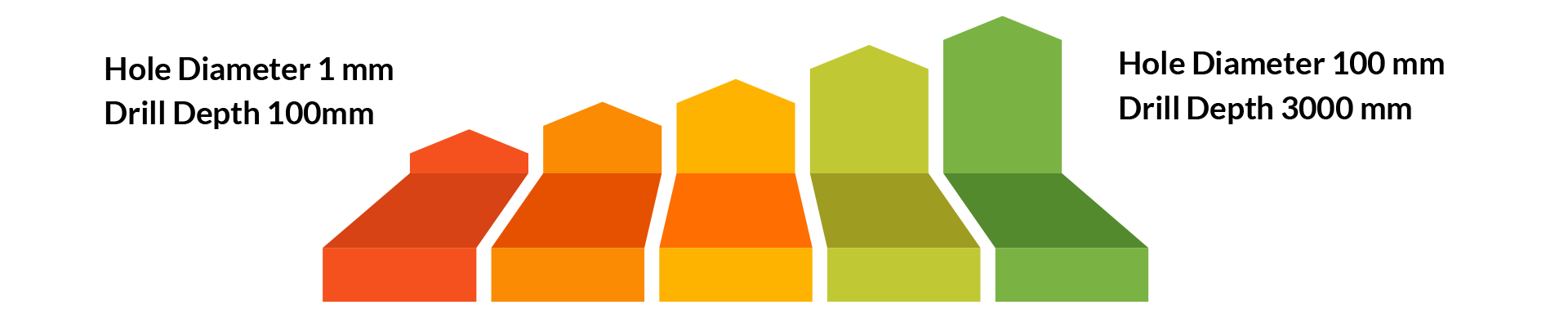

Having produced India’s first import substitute gundrilling machine in 1984, WIDMA continues to lead the way in this product category. Our competitive edge lies in understanding the entire deep hole drilling process combined with advanced design capabilities and metal-cutting expertise. Our close association with world-renowned tooling brands, access to global application databases, and the ability to design customized machines with automation and tooling has helped us innovate and deliver customer delight. We provide our customers with single-source turnkey solutions in deep-hole drilling applications.

Our machines have a wide range of features, including:

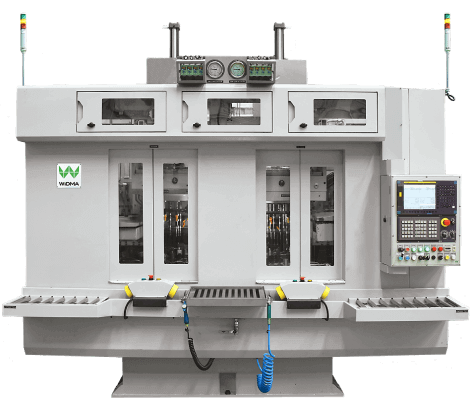

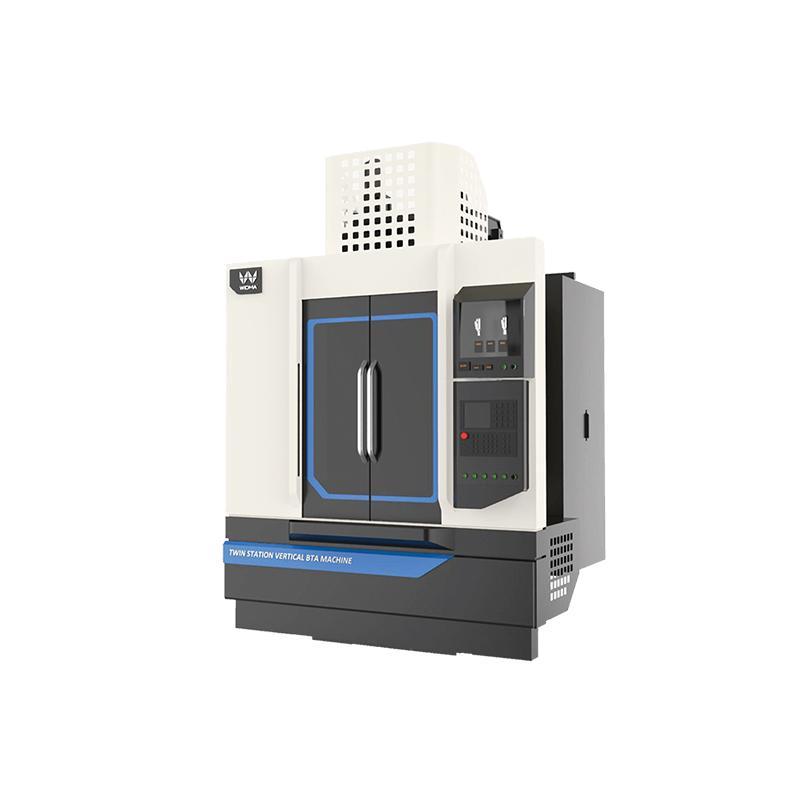

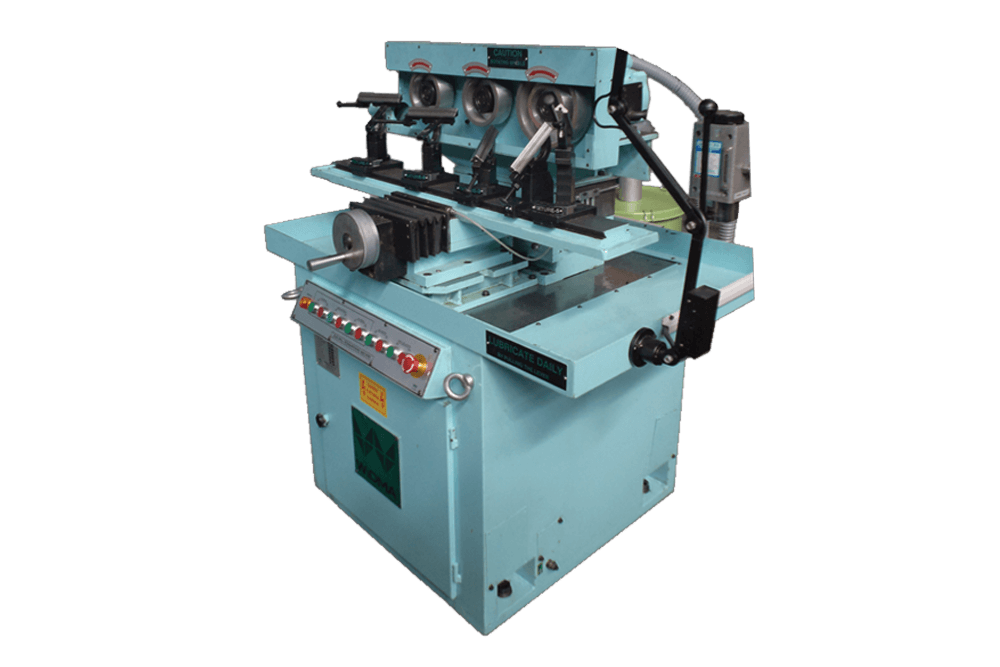

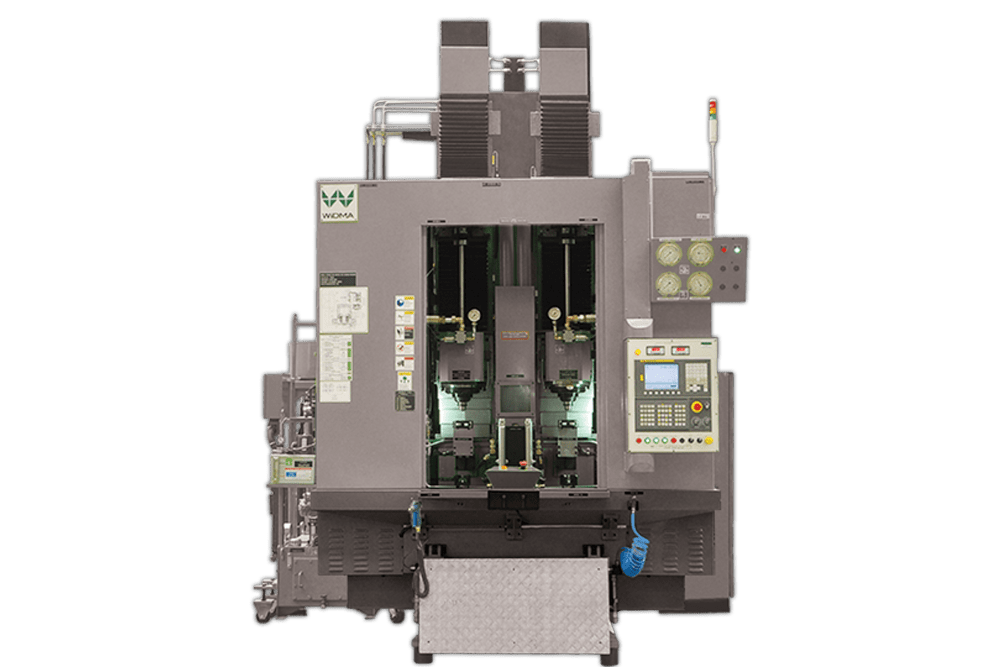

- Easy configuration that can go up from one spindle to four spindles depending on production capacity needs

- Easy detection of tool breakage and wear out

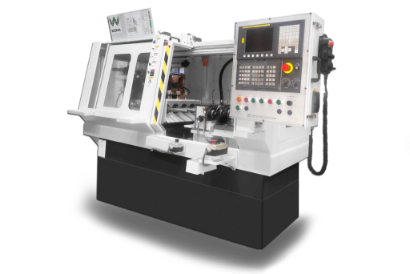

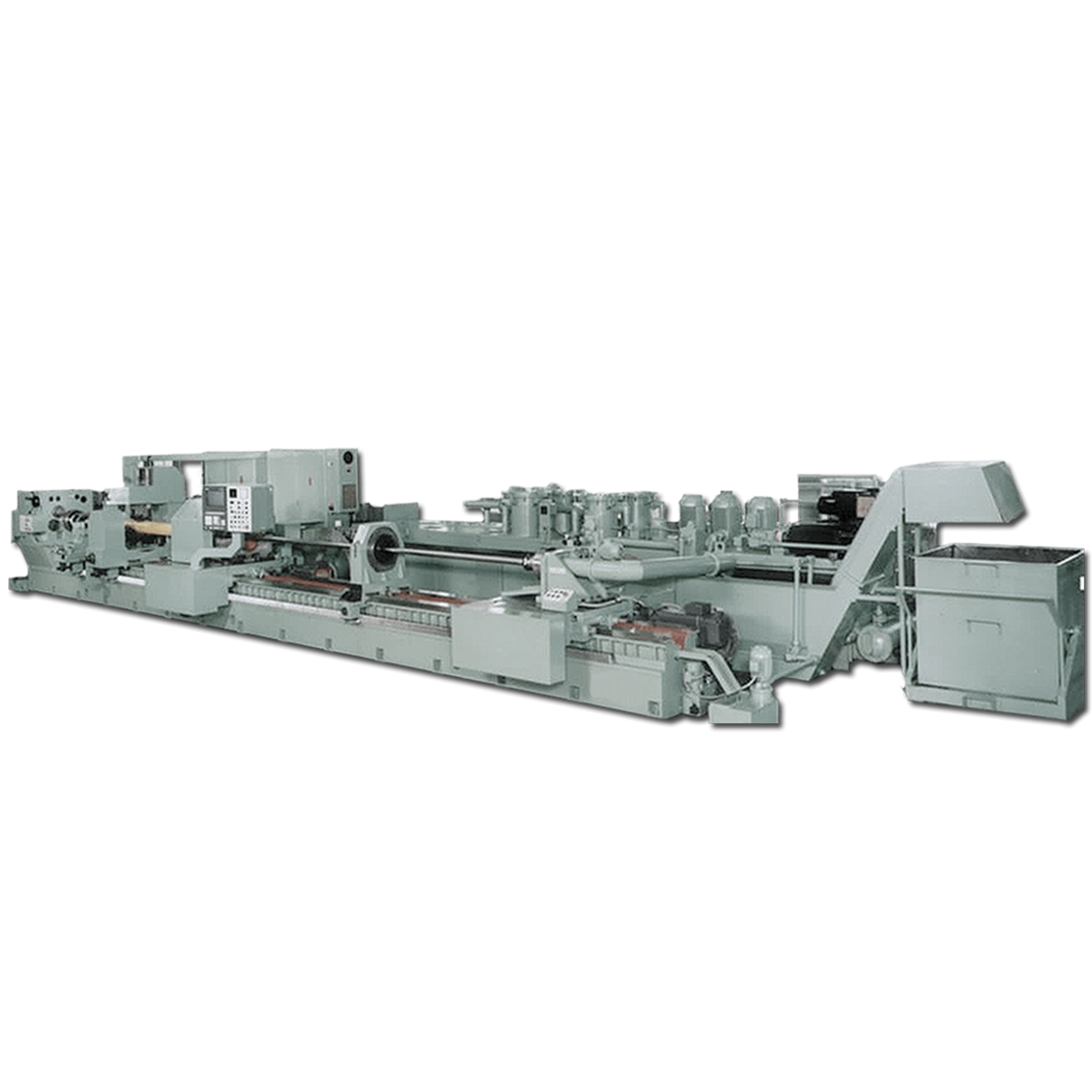

- Customized machine offering available for line production needs and tool room requirement.

- CNC system for quick setup change over for model change.

Ease of Maintenance

Multi Axis

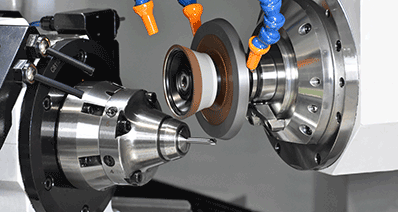

Precision & Accuracy

Automation

Turnkey Solutions

Cost Effective

Strength & Ridgity

IIoT

Ease of Maintenance

Multi Axis

Precision & Accuracy

Automation

Turnkey Solutions

Cost Effective

Strength & Ridgity