Products »

Deep Hole Drilling Machines

» Micro Gundrilling Machines (MG Series)

Products »

Deep Hole Drilling Machines

» Micro Gundrilling Machines (MG Series)

MICRO GUNDRILLING MACHINES (MG SERIES)

MICRO HOLE DRILLING MADE AT EASY

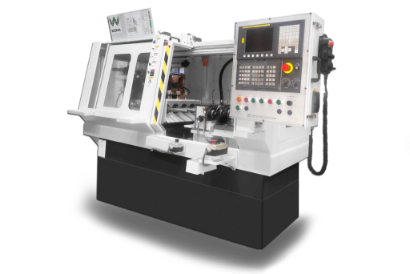

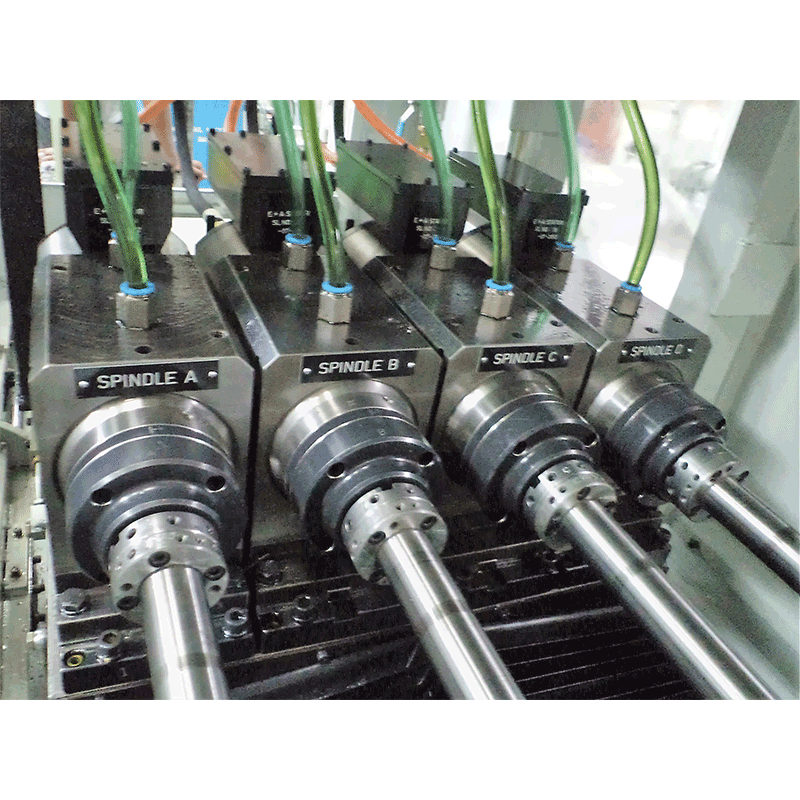

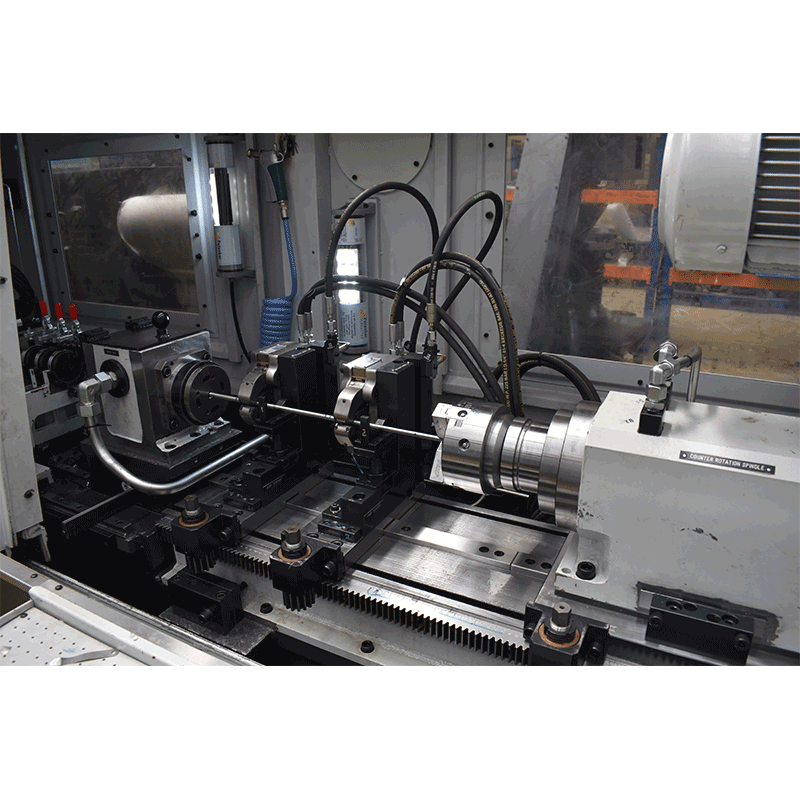

Counter Rotation Spindles

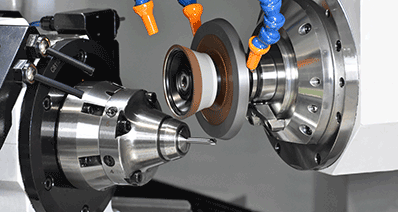

Integral Motorised Spindle

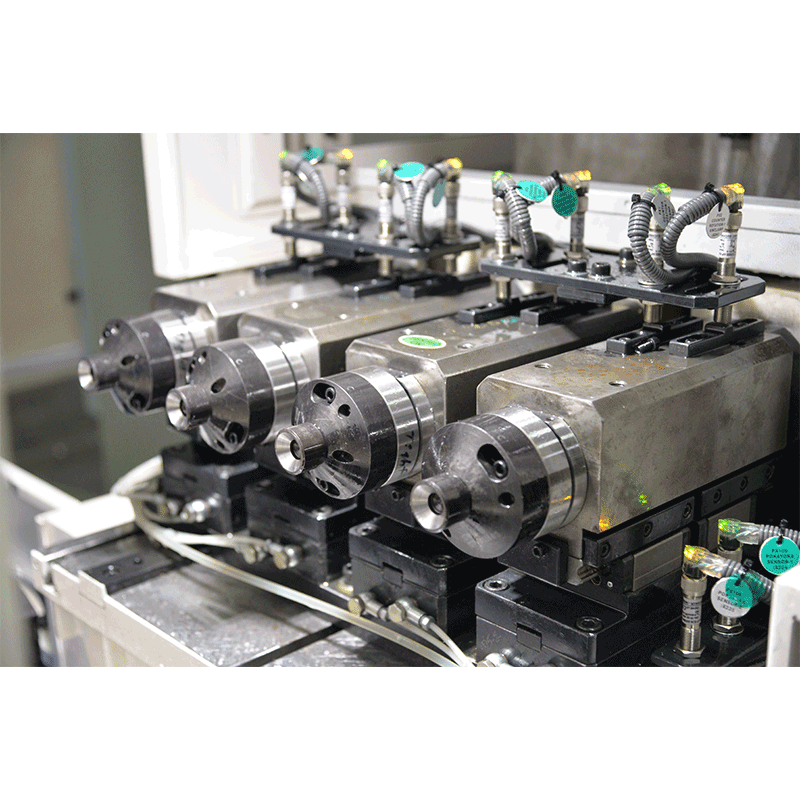

Steady Rest

Technical Specifications

| Features |

|

||

| Diameter (mm) | 1-6 | ||

| Drilling Depth (mm) | 200 | ||

| Spindle RPM | 18000 | ||

| Component Length Range (mm) | 300 | ||

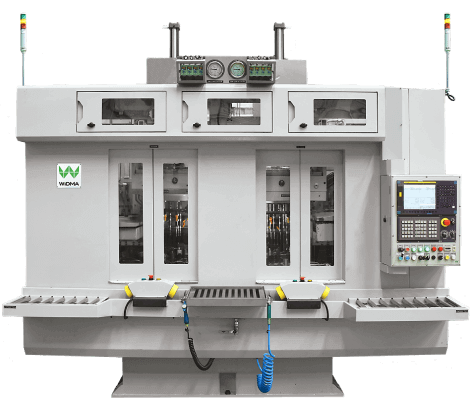

| No of Spindles | 1 | 2 | 3 | 4 |