Products »

Deep Hole Drilling Machines

» Universal Gundrilling Machines (UGC Series)

Products »

Deep Hole Drilling Machines

» Universal Gundrilling Machines (UGC Series)

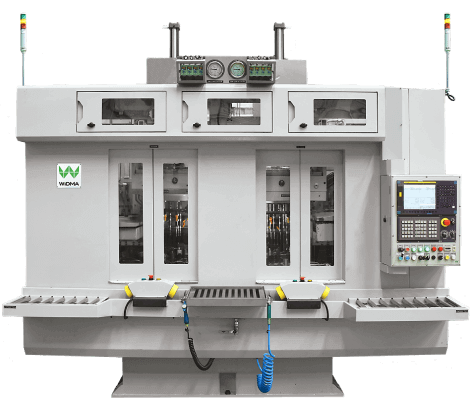

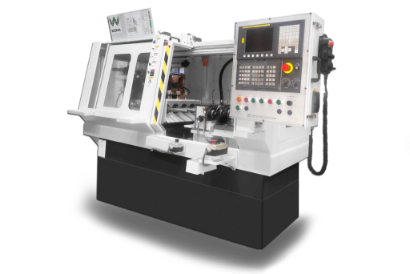

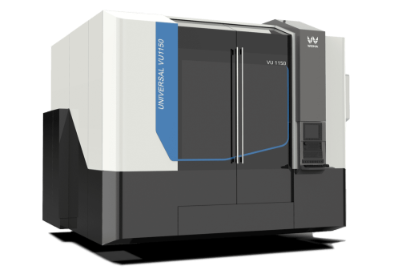

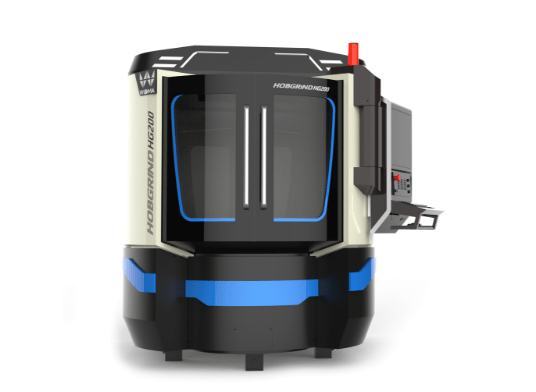

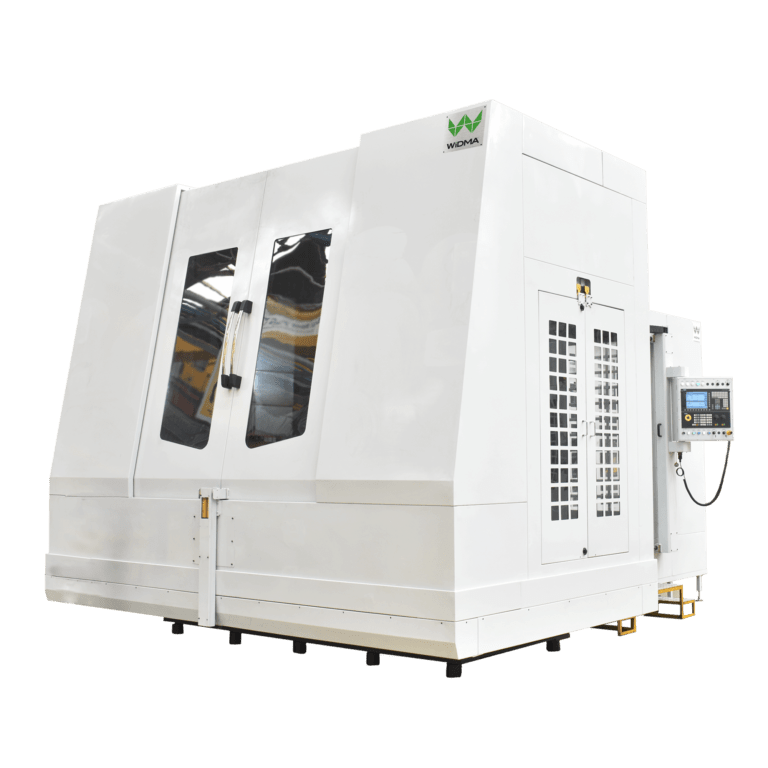

UNIVERSAL GUNDRILLING MACHINE (UGC SERIES)

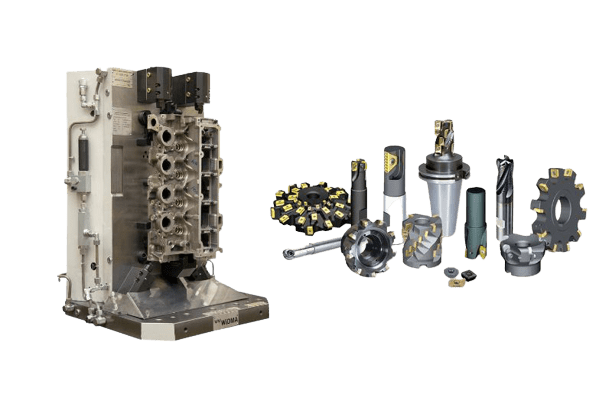

ONE MACHINE- MULTI OPERATIONS

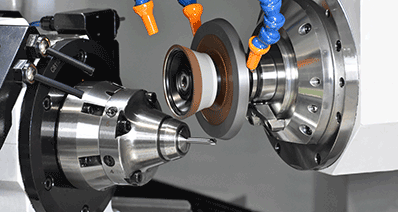

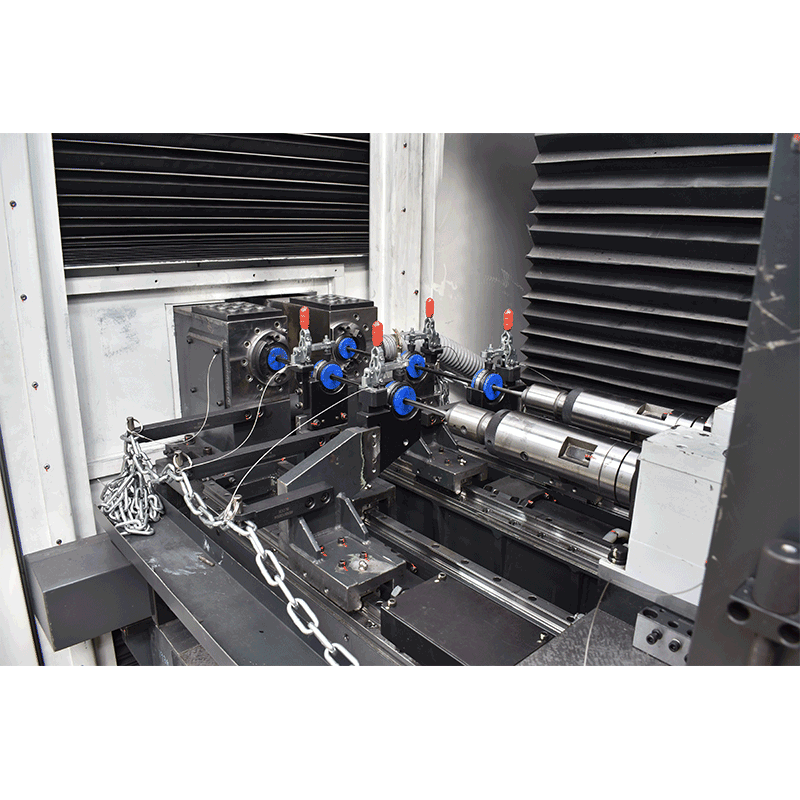

Bush Box With Adjustable Center Distance

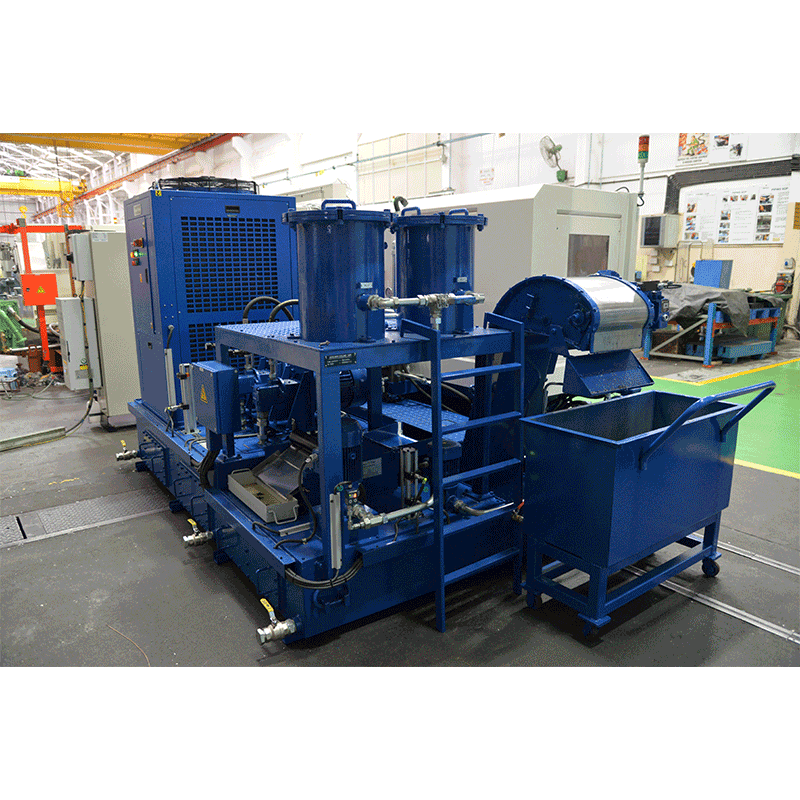

Fine Filteration Coolant System

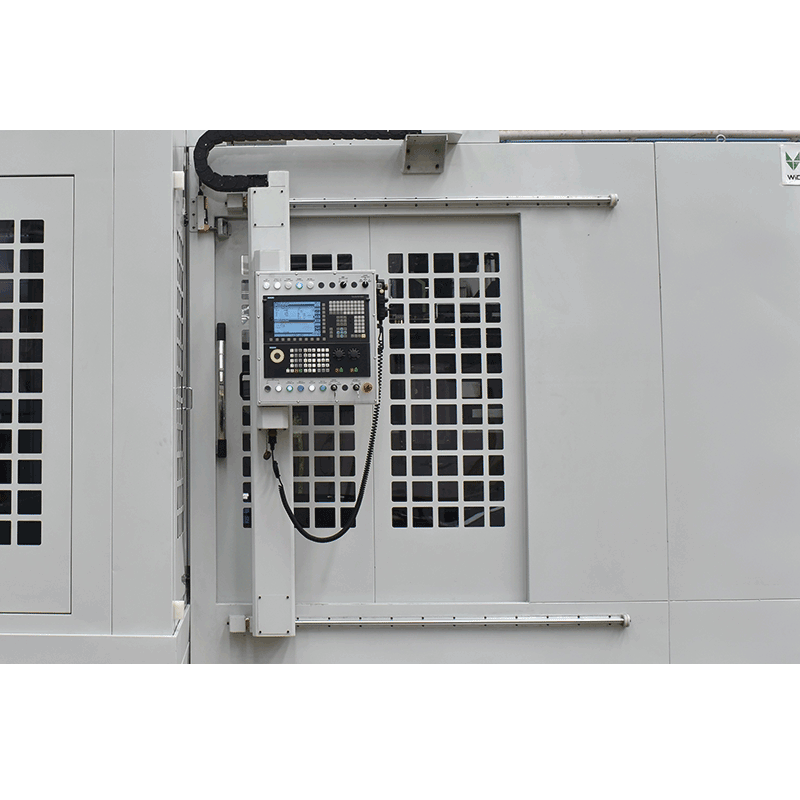

Movable Operator Panel

Technical Specifications

| Features |

|

|||||

| Diameter (mm) |

|

|||||

| Drilling Depth (mm) |

|

|||||

| Axis Stroke ( X | Y | Z) |

|

|||||

| No of Axis |

|

|||||

| Max Load (Tonnes) |

|