Products »

Flexible Manufacturing Machines

» Flex Machine for Large Components

Products »

Flexible Manufacturing Machines

» Flex Machine for Large Components

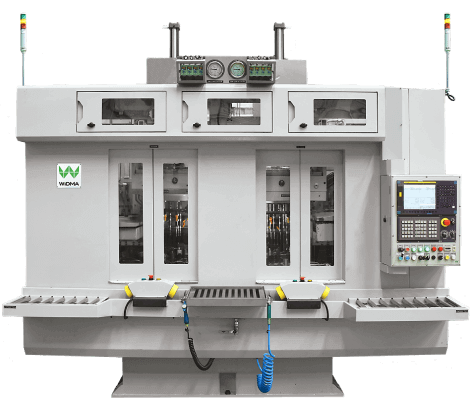

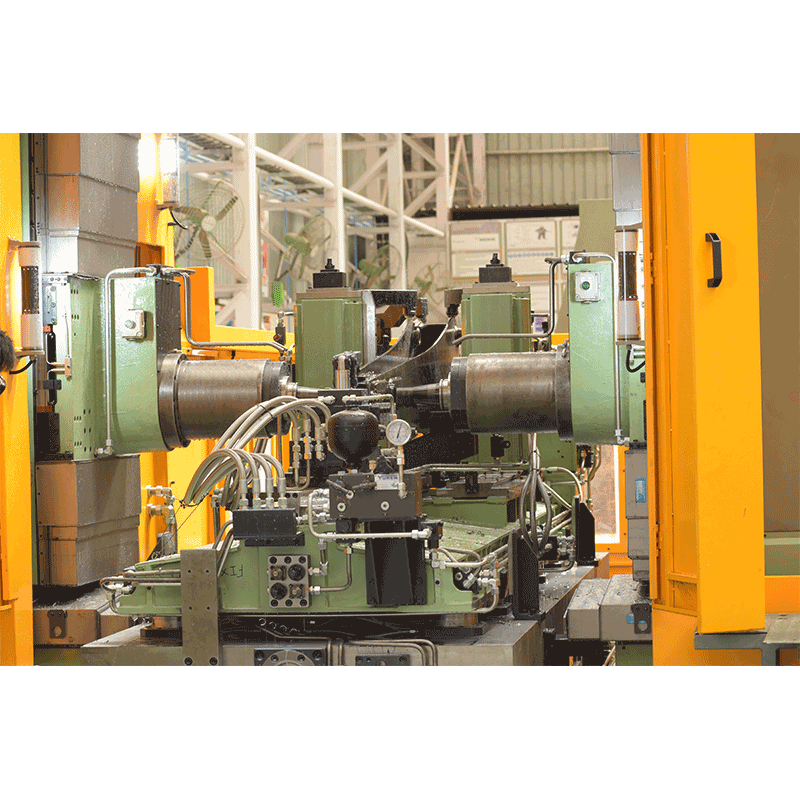

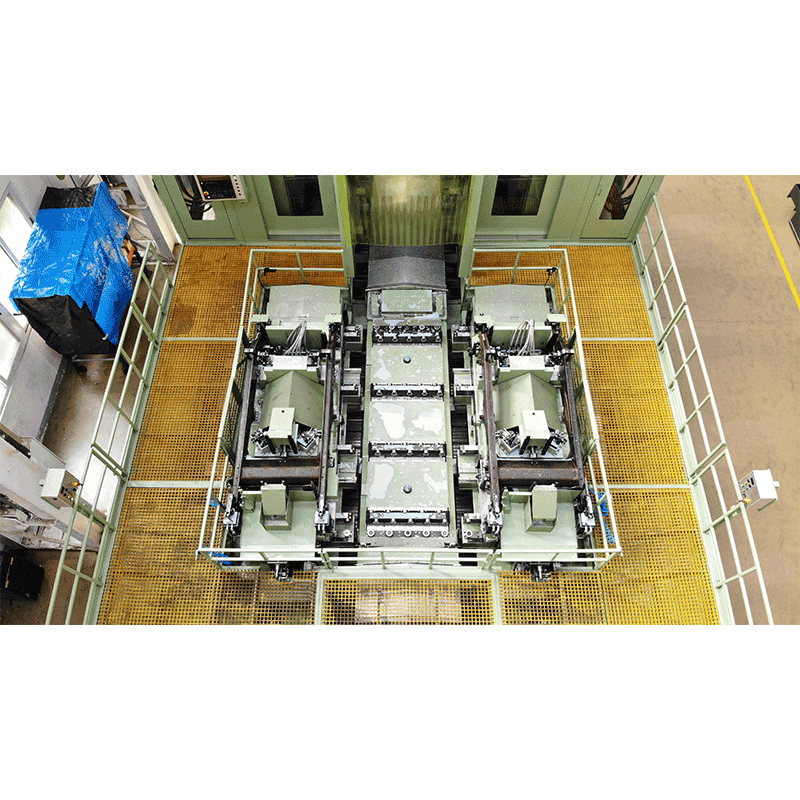

FLEX MACHINE FOR LARGE COMPONENTS

MANUFACTURE LARGE COMPONENTS WITH EASE

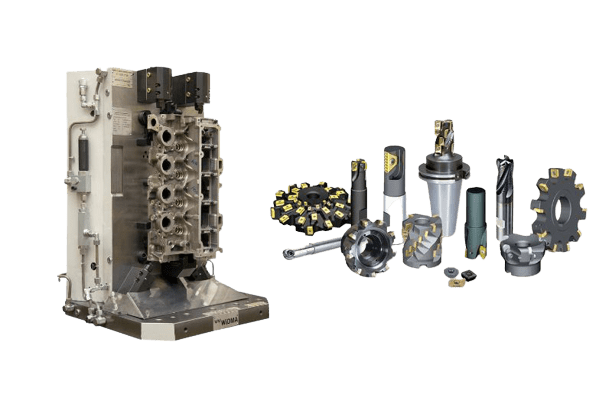

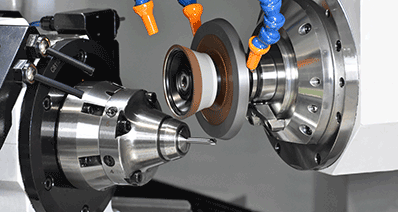

Powerful Spindles

Zero Point Clamping - Quick Change Fixture

Pallet Changer

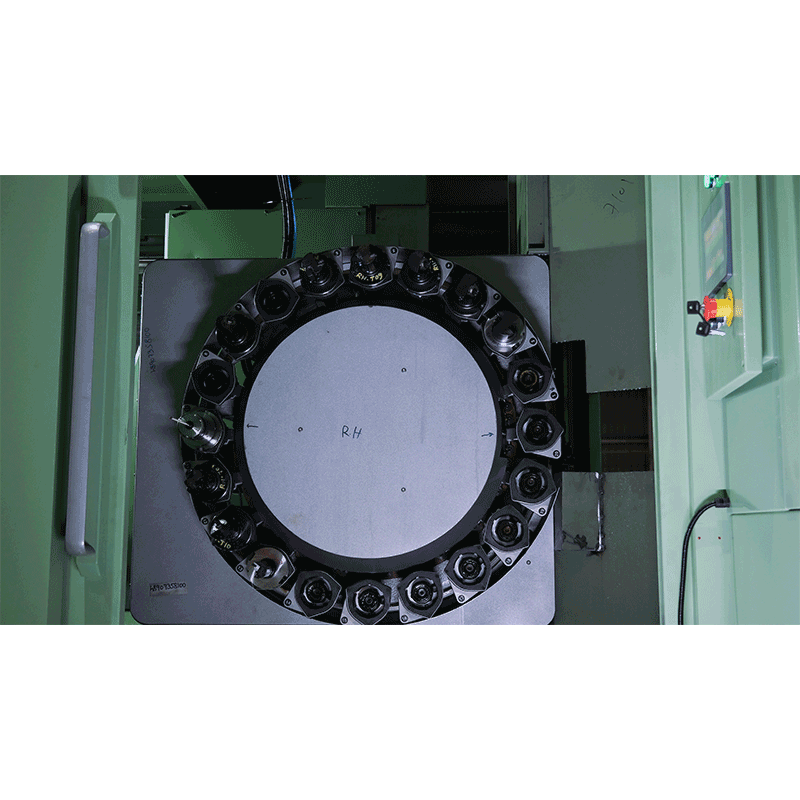

Auto Tool Changer

Technical Specifications

| TWO WAY TWO SPINDLE FLEXIBLE MACHINE | ||

| Axes movements | ||

| Total no. of axes | 7 axes | |

| Linear Axes Stroke (X/Y1&Y2/Z1&Z2) | mm | 5100/1000/900 |

| Axes Rapid rate (X/Y/Z) | m/min | 20/30/30 |

| Pallet axes 1 & 2 Stroke | mm | 1600 |

| Spindle | ||

| Spindle Type | Belt drive | |

| Power (Cont./30 mins) | kW | 11/15 (30 mins) |

| Max. RPM | RPM | 3500 |

| Spindle taper | HSK A 100 | |

| Auto Tool Magazine (ATC) | ||

| No. of tools | No. | 20 x 2 nos |

| ATC Type | Twin arm type | |

| Max Tool diameter/length (Adj. pocket full) | mm | 125 / 400 |

| Max. tool weight | kg | 15 |

| Coolant systems | bar | Thru’ coolant @15 bar |

| Machine controls | Fanuc / Mitsubishi | |

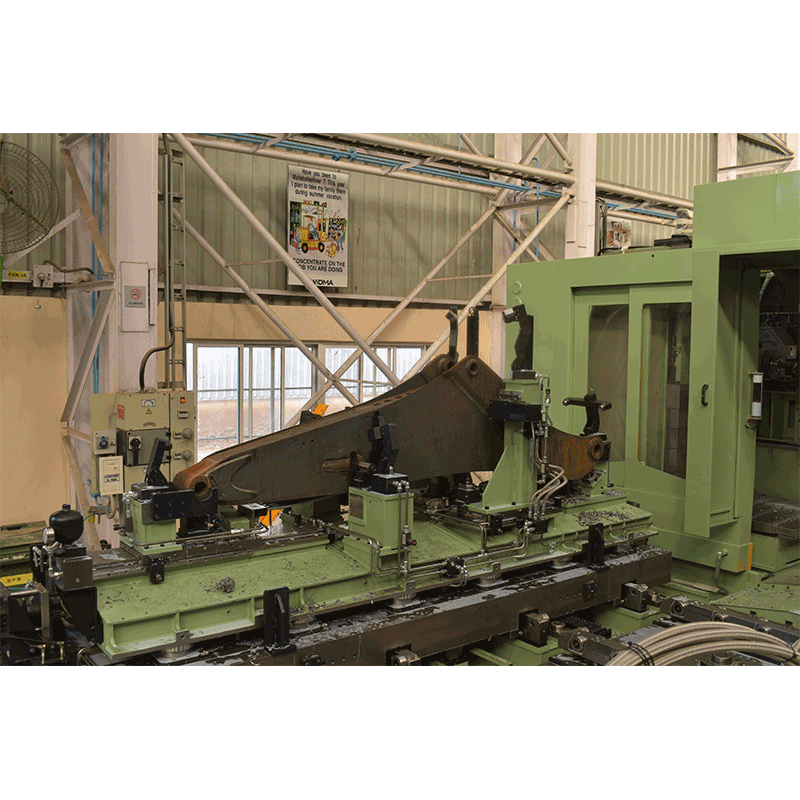

| Component capacity | ||

| Component length range | mm | 2000 – 3600 |

| Pallet | ||

| Pallet type | Ballscrew & Servo motor driven | |

| Pallet size (L x B) | mm | 1200 x 3600 |

| Machine dimensions | ||

| W x D x H | mm | 7600 x 13600 x 4500 |