Products »

Tool Grinding Machines

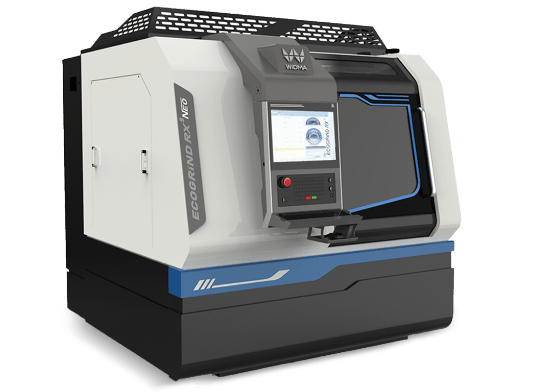

» Ecogrind RX5 NEO

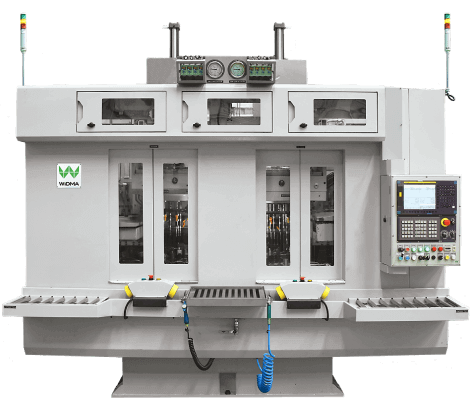

OPTIMIZE YOUR MANUFACTURING PRODUCTIVITY

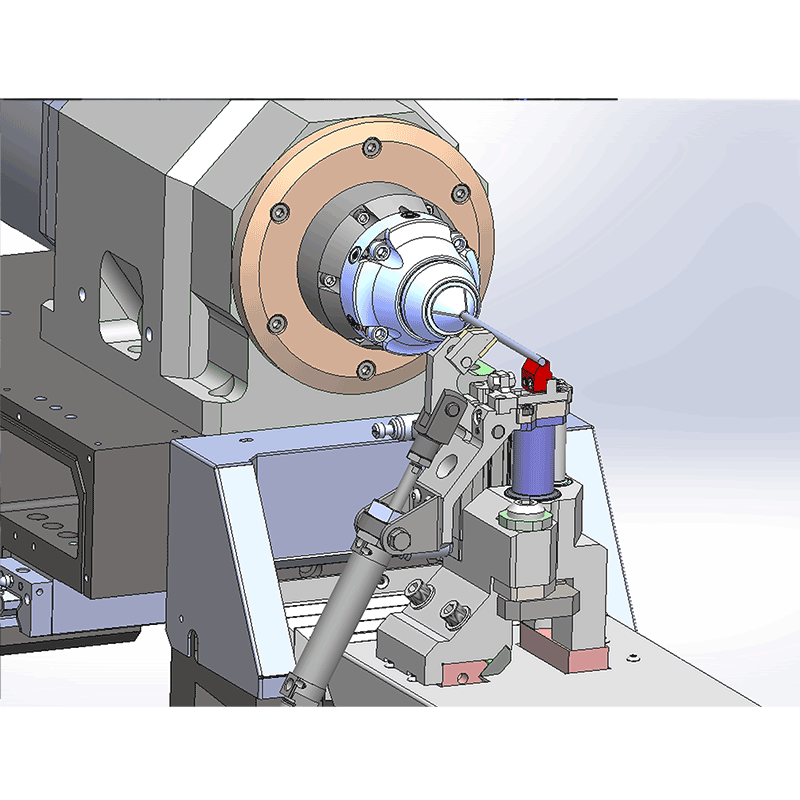

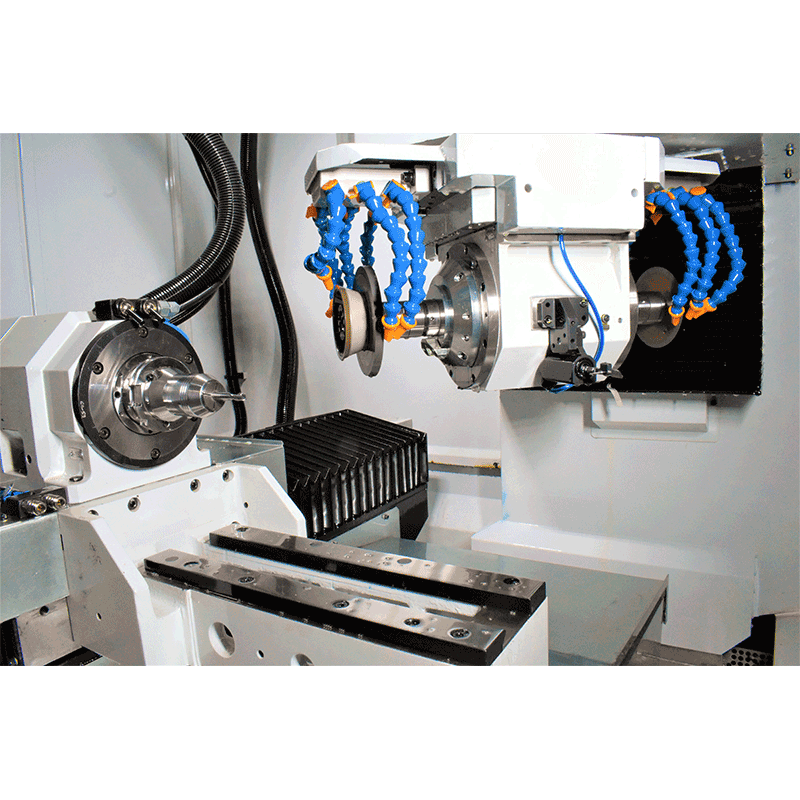

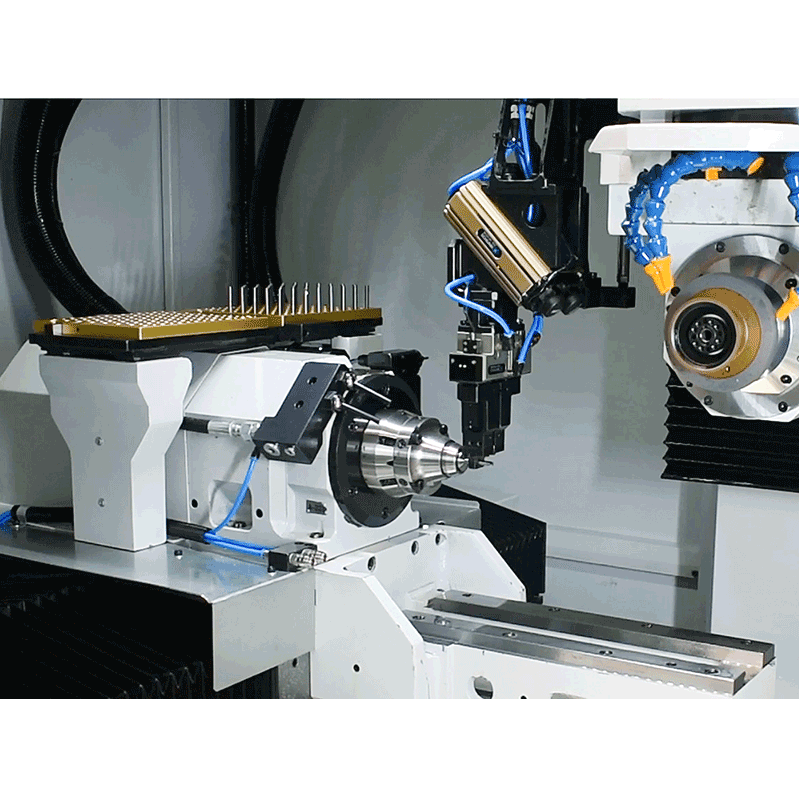

CNC Travelling Steady Rest

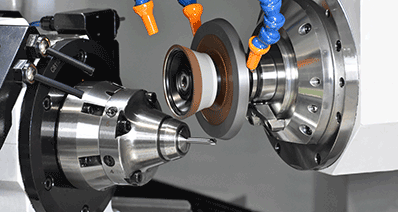

Double Ended Spindle

Compact Tool Loader

Technical Specifications

| Description | Unit | Specifications |

| Machine Capacity | ||

| No. of CNC axes | 5 | |

| Tool diameter range for manufacturing | mm | 3 to 25 |

| Max. work piece diameter for resharpening | mm | 220 |

| Max. work piece length from GPL for face grinding | mm | 320 |

| Max. work piece length from GPL for periphery (OD) grinding | mm | 490 |

| Max. work piece length from GPL for flute grinding – Helix angle 30° | mm | 415 |

| Max. work piece weight | kg | 25 |

| Linear Axes | ||

| Stroke X | Y | Z | mm | 500 | 250 | 500 |

| Rapid traverse X | Y | Z | mm | 20 | 20 | 20 |

| A-Axis (Work head) | ||

| A Axis Rotation | deg | infinite |

| Rotational Speed | RPM | 1200 |

| Spindle taper | ISO 50 | |

| B-Axis (Wheel head swivel axis) | ||

| Swivel Angle | deg | +40° / -300° |

| Rotational Speed | RPM | 50 |

| Wheel Spindle | ||

| No. of grinding spindle ends | 2 | |

| Spindle power (Coninuous | Peak) | kW | 9 | 13 |

| Max. spindle speed | RPM | 9000 |

| Spindle Nose Taper | HSK E50 | |

| Other Data | ||

| Electrical Power (Basic Machine) | kVA | 15 |

| Basic machine Floor Plan (WxDxH) | mm | 2150 x 3000 x 2200 |

| Machine Weight | kg | 6500 |

| Air requirement | CFM | 8.4 |

| Air Pressure | bar | 5 |