Products »

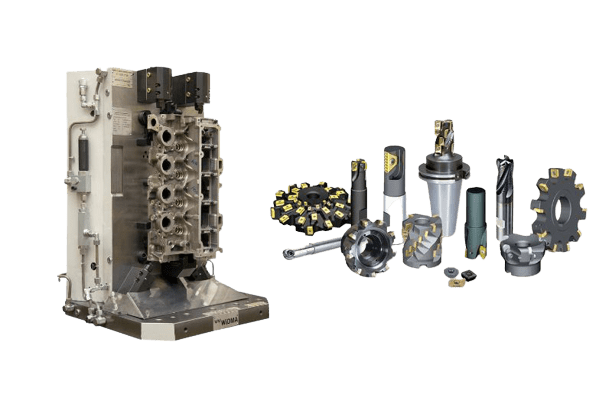

Tool Grinding Machines

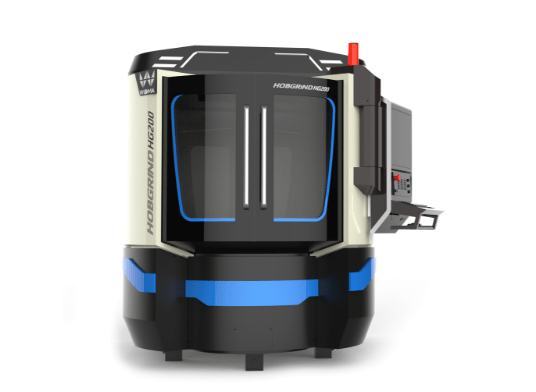

» Hobgrind HG 200

PROGRAMMED FOR PERFORMANCE

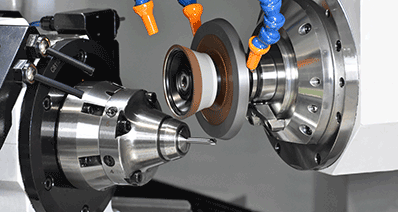

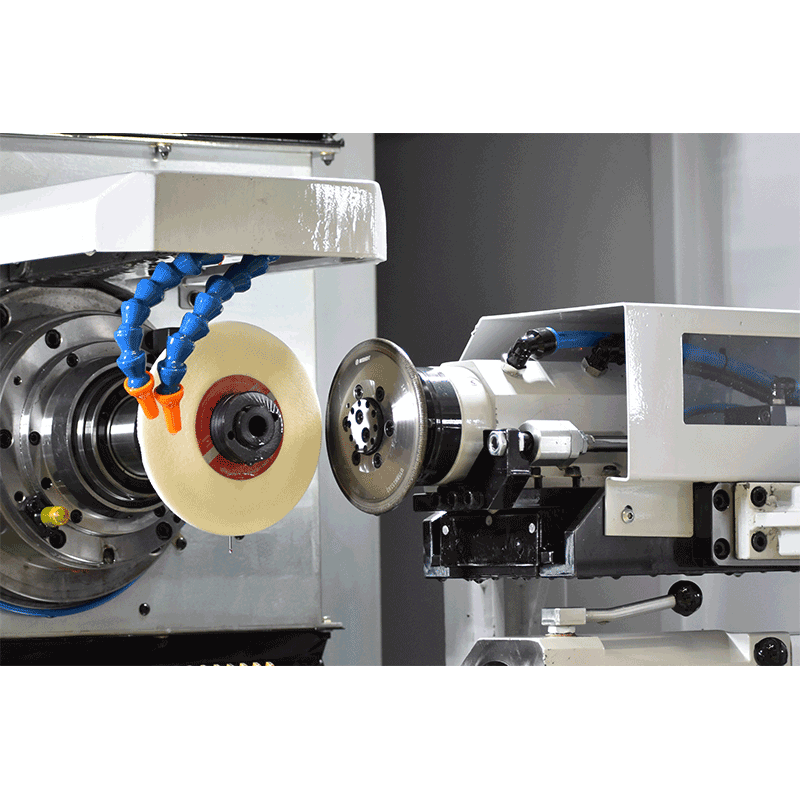

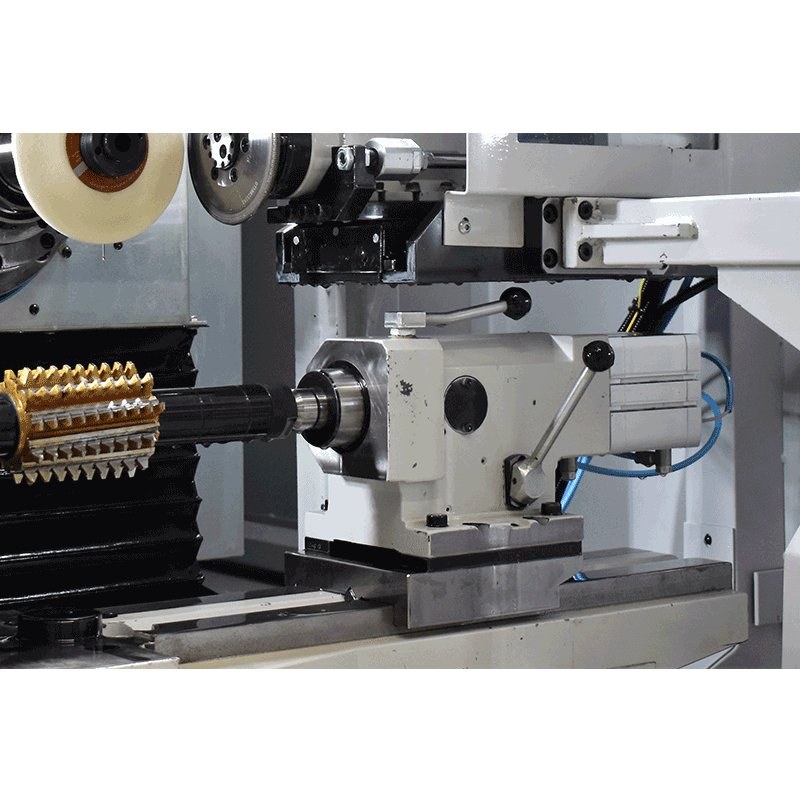

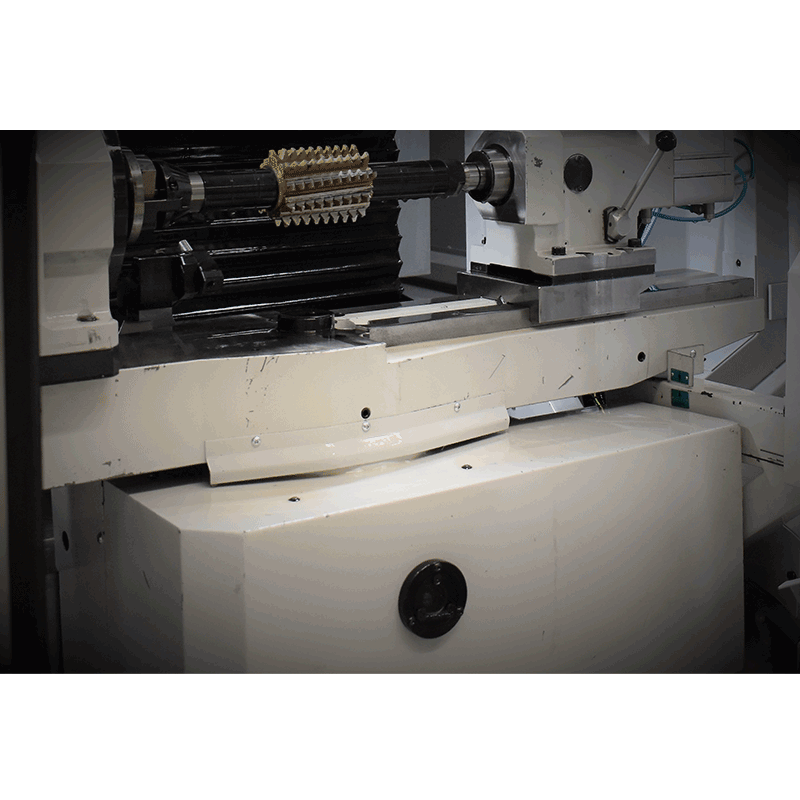

Auto Dresser for Grinding Wheels

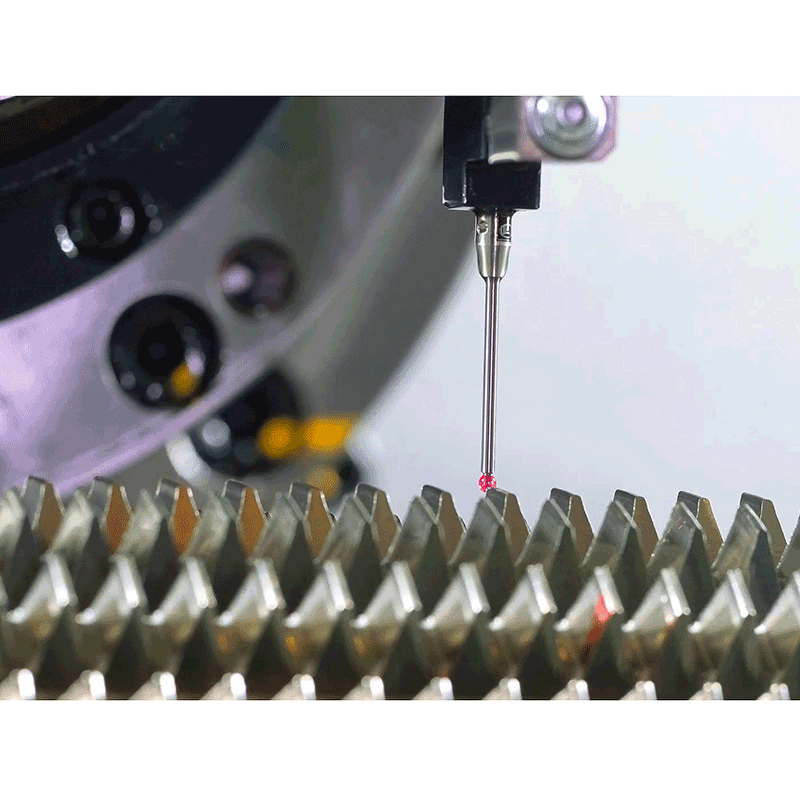

Hob Inspection Cycle

Pneumatic Tailstock

Single Cast Base Work Spindle Tailstock

Technical Specifications

| Description | Unit | Specifications |

| Machine Capacity | ||

| No. of CNC axes | 5 | |

| Hob cutter regrinding | ||

| Min. OD – Straight gash hob cutter | mm | 10 |

| Max. OD – Straight gash hob cutter | mm | 230 |

| Min. OD – Helical gash hob cutter | mm | 10 |

| Max OD – Helical gash hob cutter | mm | 180 |

| Max. length of Hob – Bore type (between centre distance) | mm | 250 |

| Max. length of Hob – Shank type (between centre distance) | mm | 550 |

| Max. grinding depth | mm | 25 |

| Max grinding length of Hob – Bore type | mm | 250 |

| Max grinding length of Hob – Shank type | mm | 250 |

| Max Helix | deg | ± 20° |

| Max Hob and Mandrel weight | Kg | 75 |

| Grinding wheel diameter – Min. / Max | mm | 50 / 150 |

| Shaper cutter regrinding | ||

| Minimum OD | mm | 20 |

| Maximum OD | mm | 230 |

| Maximum Helix Angle for Helical shaper cutter | deg | ± 20° max for Dia. 230 mm; 30 deg for Dia. 150 mm |

| Linear Axes | ||

| Stroke X | Y | Z | mm | 300 | 260 | 280 |

| Rapid traverse X | Y | Z | mm | 20 | 20 | 20 |

| A-Axis (Work head) | ||

| A Axis Rotation | deg | infinite |

| Rotational Speed | RPM | 800 |

| Spindle taper | ISO 50 | |

| B-Axis (Work head swivel axis) | ||

| Swivel Angle | deg | ± 30° |

| Rotational Speed | RPM | 10 |

| Wheel Spindle | ||

| No. of grinding spindle ends | 1 | |

| Spindle power (Coninuous | Peak) | kW | 7 | 11 |

| Max. spindle speed | RPM | 9000 |

| Other Data | ||

| Electrical Power (Basic Machine) | kVA | 15 |

| Basic machine Floor Plan (WxDxH) | mm | 2450 x 2950 x 2150 |

| Machine Weight | kg | 4500 |

| Air requirement | CFM | 4.5 |

| Air Pressure | bar | 5 |