The die and mold industry in India has been experiencing significant and consistent

growth over the years. According to researchandmarkets.com, the Indian market

alone is expected to grow by more than $1 billion from 2021 to 2025, progressing at

a CAGR of 9 percent. Driving the market is not only pent-up demand in automotive

but also substantial growth in sunrise sectors as well, including healthcare,

electronics and electricals, and plastics. In India, we must also take into

consideration aluminum metal injection molding and automation in die casting, which

are also likely contributors, along with increased construction activities and the push

to “Make in India.”

In the automotive market, OEMs are faced with the challenge of inflation as well as

productivity. Large machines where the size and complexity of the die and mold are

in high demand. Die and mold requirements are evolving, becoming more and more

complex, and requiring higher levels of machining accuracy.

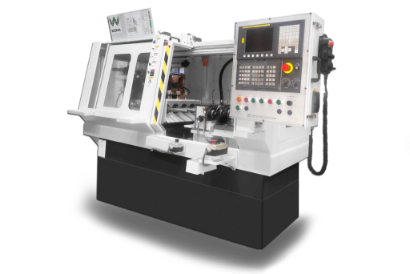

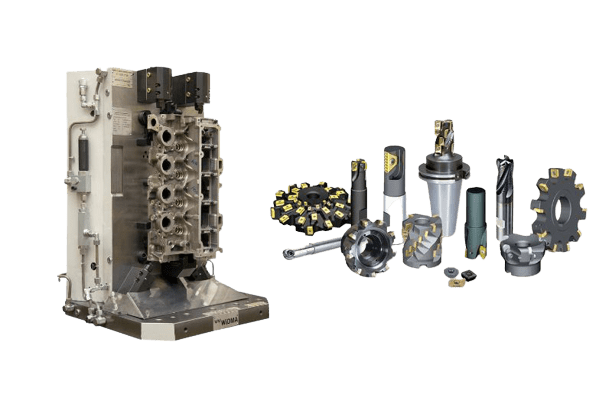

WIDMA™, a machine tool building division of Kennametal®, based in Bengaluru,

India, is helping OEMs optimize production, providing deep-hole drilling technologies

that meet the industry’s standards of accuracy, reliability, and performance.

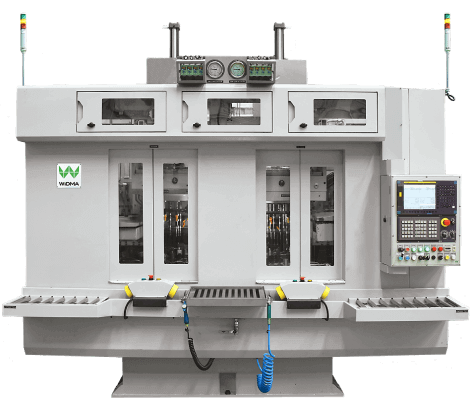

The WIDMA UGC Series Deep Hole Drilling (DHD) machine is made for high-

accuracy machining, multi-axis positioning, and deep-hole drilling in a single setup.

When designing the UGC Series, we took into consideration not only the variation in

materials to machine but also the size and complexity of the component. The UGC

Series can be configured with up to seven axes including a CNC rotary table and

spindle tilting feature, which together enable customers to drill complex angles and

structures in a single clamping setup.

To give customers the flexibility to optimize machining time and resources, UGC

Series machines can also mill, tap, and bore in addition to deep hole drilling, with

minimal set-up changes. With options to customize, the UGC Series offers drilling

depths up to 2000mm and 40mm in diameter and has the capability to support up to

30 tons.

Anticipating our customers’ needs and helping them overcome manufacturing

challenges is what we do at WIDMA. Our teams are focused on designing high-

performance machines that not only drive efficiency and productivity but are easy to

operate and low maintenance. WIDMA machines also feature adaptive machining

technology. Linear glass scales and wireless probes are also offered with UGC

Series machines.

WIDMA is a leader in providing customized metal-cutting CNC machines that offer

high accuracy and productivity across industries. Founded in 1984, WIDMA

diversified into customized, semi-standard, and standard machines for machining

requirements, ranging from micro tools to large structural parts for the locomotive

and general engineering industries. Working with some of the world’s most notable

brands, WIDMA is recognized for high-performing machines that deliver on metal

removal rates, drilling speeds, and depths.

For more information, visit https://www.widma.com/.

PRECISION AND ACCURACY EMPOWERED

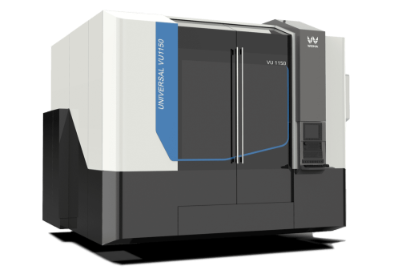

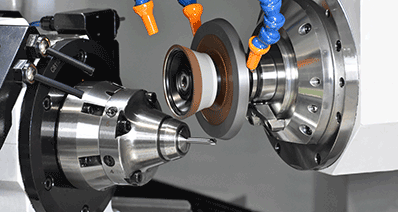

WIDMA’s Vertical Turning Lathes (VTLs) are the preferred choice for many manufacturers looking for high accuracies at high speeds. VTLs are ideal for machining components of massive size and complex geometries such as pumps and valves, railway wheels, bearings, and graphite blocks with accuracy. Many of our customers have benefited from upgrading their conventional set-ups to our machines. The resulting productivity boost and quality improvement are direct results of reduced cycle times and improved accuracies. Ranging from simple turning to complex 5-face machining, these machines are classified under three categories- Multi-Tasking Turn Mill Machines (VU), Vertical Turn Mill Machines (VM), and Vertical Turning Machines (VT) – from two-axes to five-axes configurations with table sizes ranging from 500 mm to 3000 mm.

The VU-5 Axis Multi-Tasking Turn Mill Machine is an industry leading offering from WIDMA that offers high accuracy, precision, and versatility. With their ability to perform multiple machining operations on a single workpiece, they reduce setup time, improve accuracy, enhance productivity, and offer cost-effective solutions. VU-5 Axis Multi-Tasking Turn Mill Machines find applications in several industries, making them a preferred choice for manufacturing complex parts.

The WIDMA UGC Series Deep Hole Drilling (DHD) machine is made for high-

accuracy machining, multi-axis positioning, and deep-hole drilling in a single setup.

When designing the UGC Series, we took into consideration not only the variation in

materials to machine but also the size and complexity of the component. The UGC

Series can be configured with up to seven axes including a CNC rotary table and

spindle tilting feature, which together enable customers to drill complex angles and

structures in a single clamping setup.

To give customers the flexibility to optimize machining time and resources, UGC

Series machines can also mill, tap, and bore in addition to deep hole drilling, with

minimal set-up changes. With options to customize, the UGC Series offers drilling

depths up to 2000mm and 40mm in diameter and has the capability to support up to

30 tons.

Anticipating our customers’ needs and helping them overcome manufacturing

challenges is what we do at WIDMA. Our teams are focused on designing high-

performance machines that not only drive efficiency and productivity but are easy to

operate and low maintenance. WIDMA machines also feature adaptive machining

technology. Linear glass scales and wireless probes are also offered with UGC

Series machines.

WIDMA is a leader in providing customized metal-cutting CNC machines that offer

high accuracy and productivity across industries. Founded in 1984, WIDMA

diversified into customized, semi-standard, and standard machines for machining

requirements, ranging from micro tools to large structural parts for the locomotive

and general engineering industries. Working with some of the world’s most notable

brands, WIDMA is recognized for high-performing machines that deliver on metal

removal rates, drilling speeds, and depths.

For more information, visit https://www.widma.com/.

PRECISION AND ACCURACY EMPOWERED

WIDMA’s Vertical Turning Lathes (VTLs) are the preferred choice for many manufacturers looking for high accuracies at high speeds. VTLs are ideal for machining components of massive size and complex geometries such as pumps and valves, railway wheels, bearings, and graphite blocks with accuracy. Many of our customers have benefited from upgrading their conventional set-ups to our machines. The resulting productivity boost and quality improvement are direct results of reduced cycle times and improved accuracies. Ranging from simple turning to complex 5-face machining, these machines are classified under three categories- Multi-Tasking Turn Mill Machines (VU), Vertical Turn Mill Machines (VM), and Vertical Turning Machines (VT) – from two-axes to five-axes configurations with table sizes ranging from 500 mm to 3000 mm.

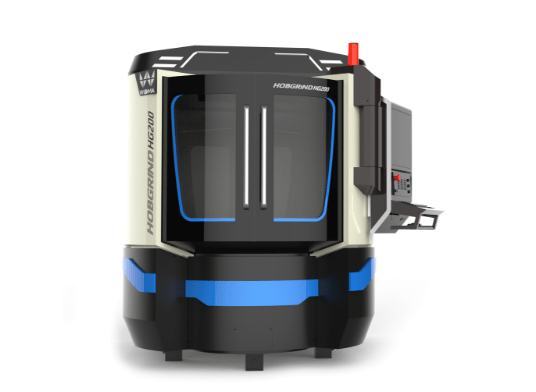

The VU-5 Axis Multi-Tasking Turn Mill Machine is an industry leading offering from WIDMA that offers high accuracy, precision, and versatility. With their ability to perform multiple machining operations on a single workpiece, they reduce setup time, improve accuracy, enhance productivity, and offer cost-effective solutions. VU-5 Axis Multi-Tasking Turn Mill Machines find applications in several industries, making them a preferred choice for manufacturing complex parts.

Key Features:

-

5-Axis Machining Capability: The VU-5 Axis Multi-Tasking Turn Mill Machines offer 5-axis machining capability that enables them to perform complex machining operations with high accuracy and precision.

-

Dual Spindles: The machines are equipped with dual spindles that allow them to perform simultaneous machining operations on both ends of the workpiece.

-

Automatic Tool Changer: The machines come with an automatic tool changer that can quickly change the cutting tools to perform different machining operations.

-

High-Speed Machining: VU-5 Axis Multi-Tasking Turn Mill Machines have high-speed machining capabilities, which help to reduce machining time and improve productivity.