Products »

Vertical Turning Lathes

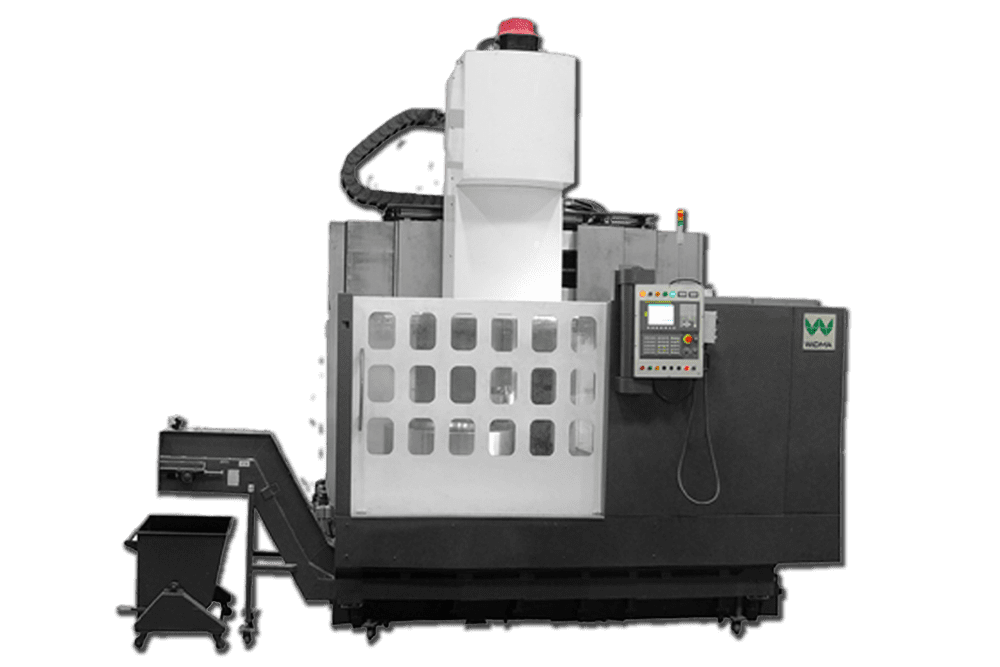

» VM Series – Ram Type Turn-mill Centers

Products »

Vertical Turning Lathes

» VM Series – Ram Type Turn-mill Centers

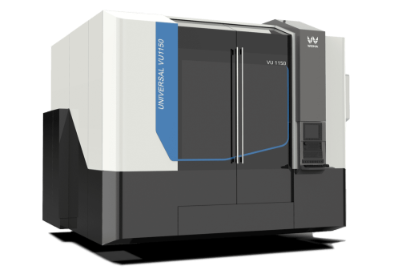

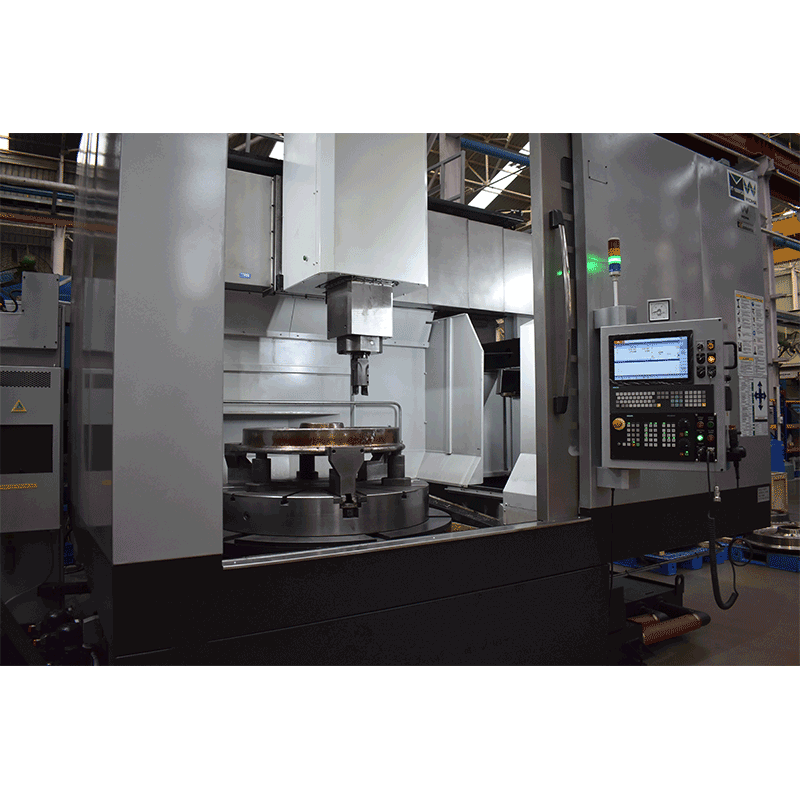

VM Series – Ram Type Turn-mill Centers

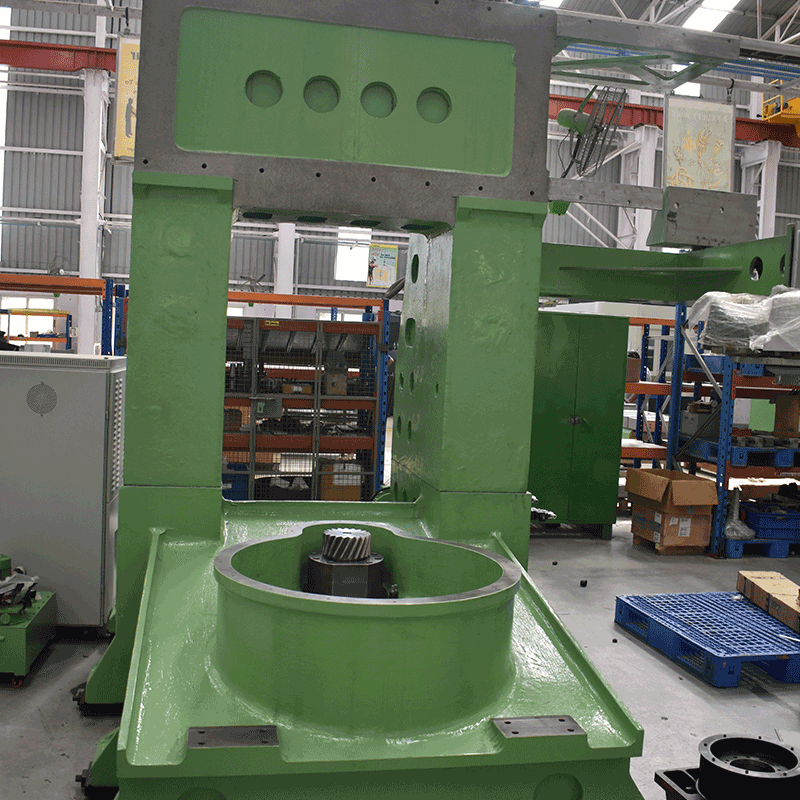

Rigid Machine Base

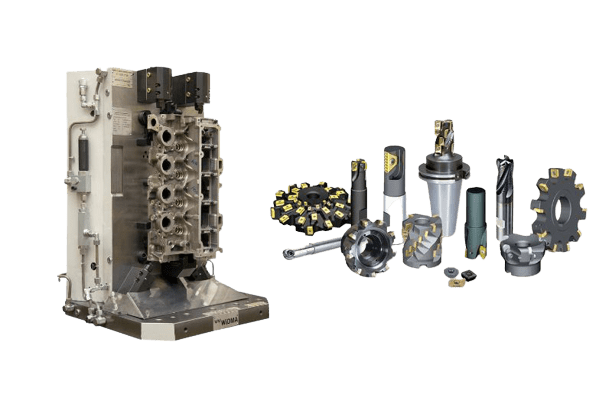

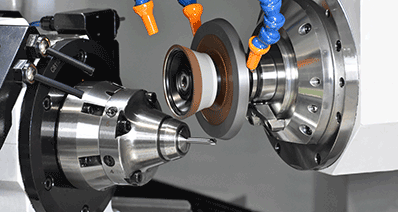

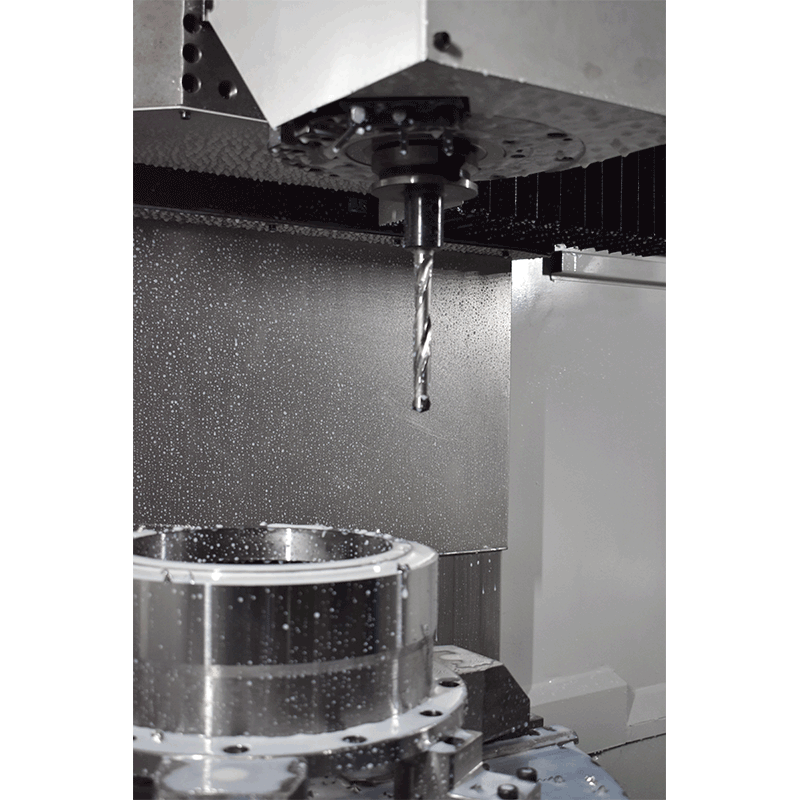

Ram Spindle

Live Tool Spindle

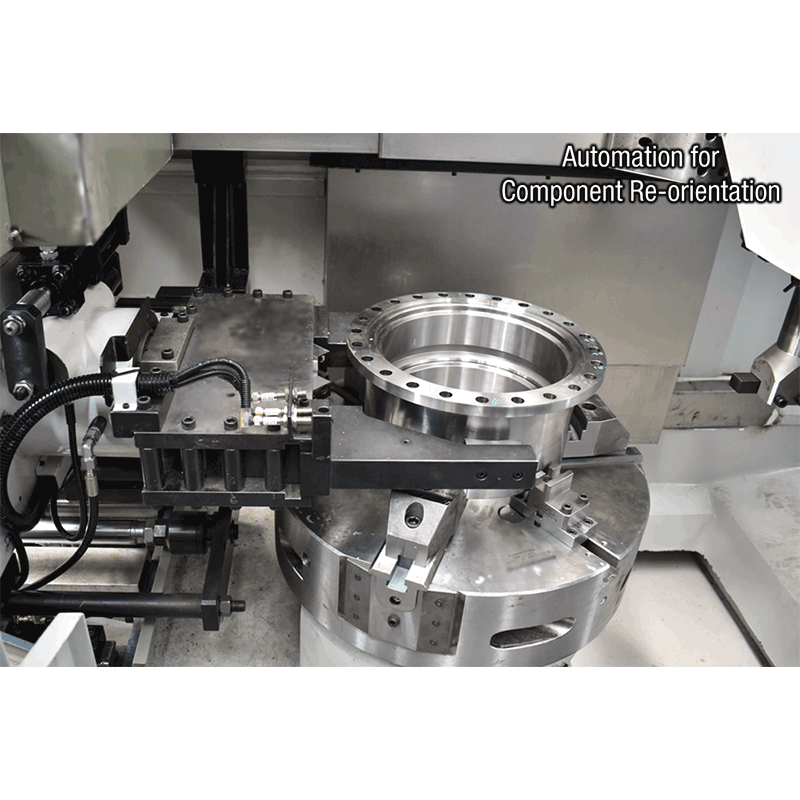

Automation for Component Handling

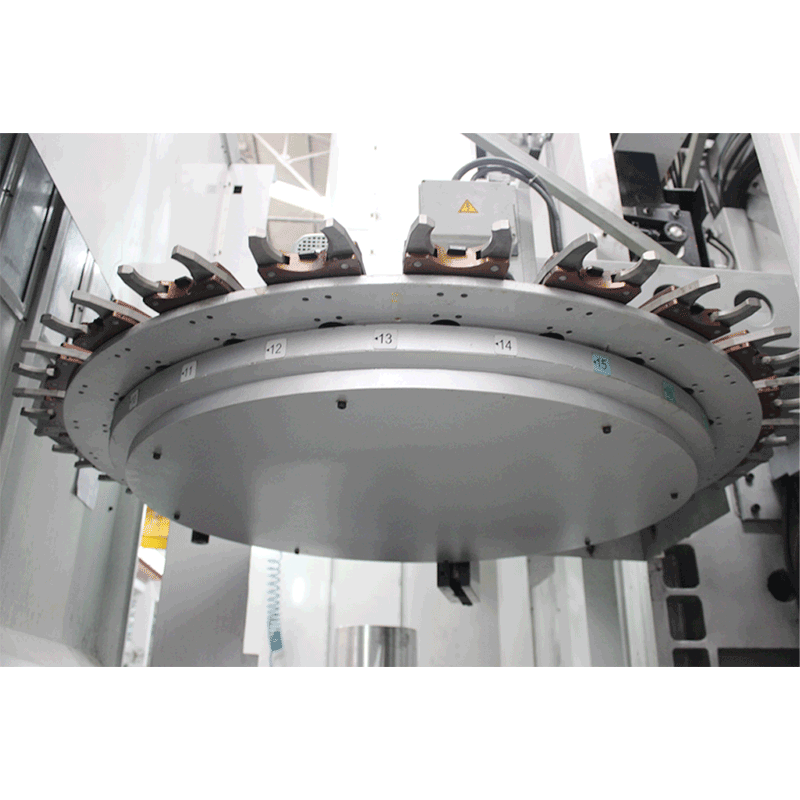

Auto Tool Changer

Technical Specifications

| Features | Unit |

|

|||||||

| Machine Capacity | |||||||||

| Maximum table diameter | mm |

|

|||||||

| Standard turning diameter | mm |

|

|||||||

| Swing Over Bed | mm |

|

|||||||

| Maximum turning height | mm |

|

|||||||

| Maximum weight of the job | Kg |

|

|||||||

| Work spindle | |||||||||

| Power (Continuous | 30 min.) | kW |

|

|||||||

| Live Spindle (BT50) | |||||||||

| Power (Continuous | 30 min.) | kW |

|

|||||||

| Maximum RPM | RPM |

|

|||||||

| Axis | |||||||||

| Construction |

|

||||||||

| Ram Cross section | mm |

|

|||||||

| Tool station | |||||||||

| Type |

|

||||||||

| No. of tools (Std. | Optional) | No. |

|

|||||||

| Weight (approx.) | Kg |

|